Stokes Microvac piston pump

Description

The Stokes Microvac rotary piston pump has set the standard for performance, efficiency, reliability and reparability in the industry for more than 80 years. The Stokes Microvac J-Series rotary piston pump has been improved, upgraded and tuned to provide even better reliability and productivity combined with minimal maintenance and process downtime. An integrated oil distribution system eliminates external piping connections and ensures tight operating conditions, all in a stylized design. A stiffer engine mounting platform reduces flexibility to minimize engine belt wear. A stylized oil reservoir cover and O-rings on the side cover improve tightness and eliminate the risk of oil leakage. An integrated equalization valve built into the side cover allows quick adaptation to automatic steam control mode.

A wide range of versatile accessories are available along with the ability to integrate with a range of mechanical booster pumps, making the Stokes Microvac easily adaptable to the requirements of a given vacuum process.

Specification

Reliability – proven performance for over 80 years along with experienced Edwards service and support

Reliability – low speed for longest possible pump life

Robust design – easy on-site maintenance; robust simple mechanism for high reliability and easy conversion at any time

Configuration flexibility – possible retrofit with a wide range of mechanical pump amplifiers

State-of-the-art technology – continuous investment in design and improvement of existing technology

No unplanned downtime – trouble-free pumping with full warranty and after-sales support

Technical parameters

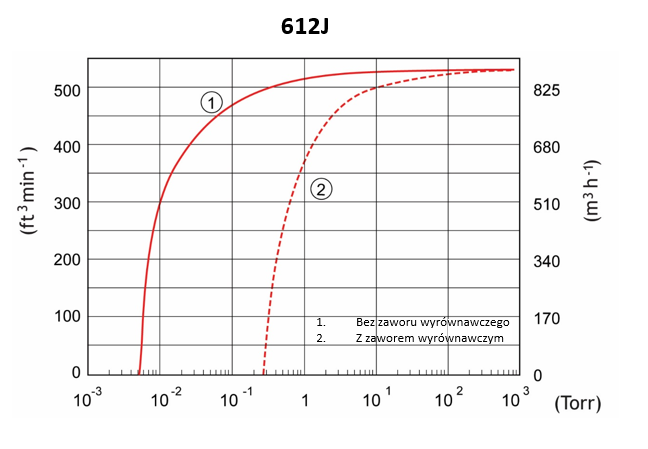

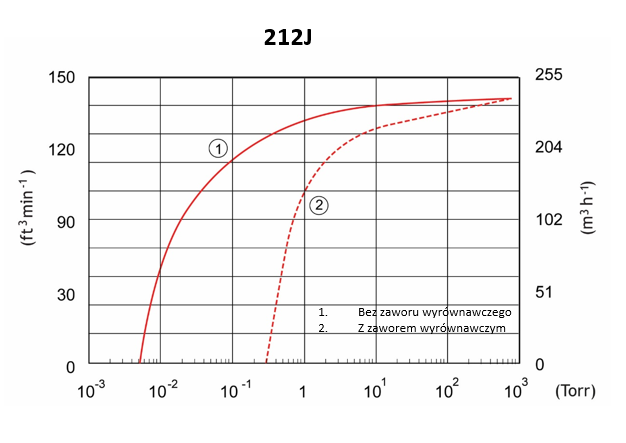

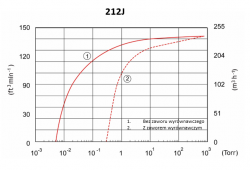

| Units of measurement | 212J | 412J | 612J | |

| Pumping capacity | m3h-1 / ft3min-1 | 255 / 150 | 510 / 300 | 1020 / 600 |

| Pumping speed | m3h-1 / ft3min-1 | 234 / 138 f | 442 / 260 | 884 / 520 |

| The ultimate vacuum | ||||

| Without equalization valve | mbar / Torr | < 3,3×10-2 / < 2,5×10-2 | < 3,3×10-2 / < 2,5×10-2 | < 3,3×10-2 / < 2,5×10-2 |

| With compensating valve | mbar / Torr | < 2,6×10-1 / < 2×10-1 | < 2,6×10-1 / < 2×10-1 | < 2,6×10-1 / < 2×10-1 |

| 50 Hz motor | kW IEC (CE variant) | 5,5 | 11 | 11 |

| 60 Hz motor | hp TEFC | 7,5 | 10 | 10 |

| Motor speed | rpm | 1800 | 1800 | 1800 |

| Input connection | flange ASA/ANSI 3” | flange ASA/ANSI 4” | flange ASA/ANSI 6” | |

| Exhaust connection | flange ASA/ANSI 2” lub NPT 2” | flange ASA/ANSI 3” lub NPT 3” | flange ASA/ANSI 2 x 3” lub NPT 3” | |

| Water inlet/outlet connection | NPT 1/2 inch | NPT 1/2 inch | NPT 1/2 inch x 2 | |

| Recommended cooling flow at 85oC / 30oF | lmin-1 / galmin-1 | 5,7 / 1,5 | 7,6 / 1,5 | 7,6 / 1,5 |

| Steam pumping speed | kgh-1 / lbh-1 | 5 / 11 | 10,45 / 23 | 20,9 / 46 |

| Oil capacity | l / gal | 2 / 4 | 46 / 12 | 92 / 24 |

| Recommended oil | V lube F | V lube F | V lube F | |

| Noise level generated | dB(A) | < 77 | < 83 | < 85 |

| Weight | kg / lbs | 431 / 950 | 794 / 1750 | 1724 / 3800 |

Application

• Automotive industry

• General applications

• Metallurgy

• Vacuum deposition of coatings

• Vacuum melting

• Chemical processes

• Heat treatment

• Leak detection

• PET packaging

• Drug manufacturing

• Transformer drying