Screw pumps GXS160, GXS250, GXS450 & GXS750

Description

The competitive nature of today’s business means changes are required to improve performance, lower costs, and provide optimal process solutions. The dry pumping solution is the change from traditional oil sealed pumps to a proven technology for this industry. Edwards, a world leader in dry pump technology, has demonstrated the ability to provide a low-cost, tailored solution to your vacuum application.

Specification

Maintenance

• Low capital cost and minimal maintenance requirements lead to lowest cost of ownership.

• Extended periods between user intervention.

• Lower consumable costs.

Environmental

• No oil disposal.

• No oil emissions into atmosphere.

Performance

• Very stable pumping speed gives repeatability to processes.

• Continuous pumping at atmosphere.

• Ability to handle particulates.

• Dry eliminates back-streaming, thus protecting reactive alloys from contamination.

Safety

• Unobtrusive noise levels.

• No unsightly oil spills.

• No hazardous oil vapours.

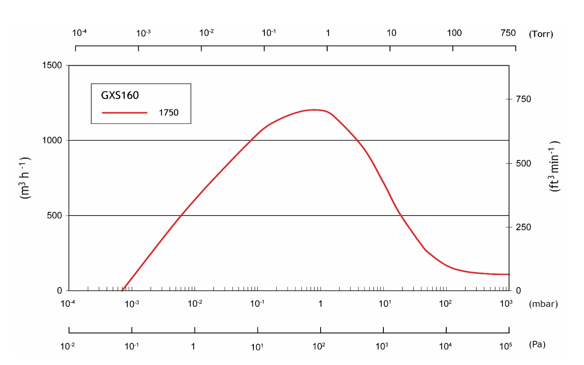

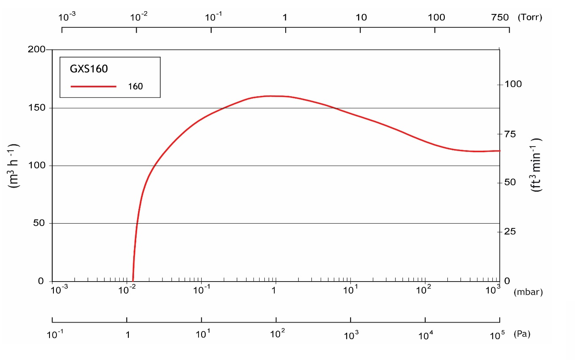

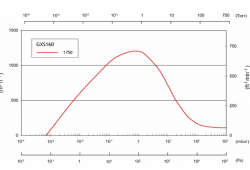

GXS160 Dry Pump

| Units | GXS160 | GXS160/1750 | ||

| Peak Pumping Speed | m3h-1 (cfm) | 160 (94) | 1200 (706) | |

| Ultimate Pressure (without purge) | mbar (Torr) | 7 x 10-3 (5,3 x 10-3) | 7 x 10-4 (5,3 x 10-4) | |

| Full Load Power | @ ultimate pressure | kW (hp) | 3,8 (5,1) | 5,1 (6,8) |

| @ peak pumping load | kW (hp) | 5,0 (6,7) | 7,4 (9,9) | |

| Electrical | Supply options | High volt | 380 – 460V 3Ø 50/60Hz | |

| Low volt | 200 – 230V 3Ø 50/60Hz | |||

| Connection | High volt | Harting Han K 4/4-F | ||

| Low volt | ||||

| Vacuum Couplings | Inlet | ISO63 | ISO100 | |

| Exhaust | NW40 | |||

| Cooling Water | Supply pressure (max) | bar (psig) | 6,9 (100) | |

| DP(1) across pump (min) | bar (psig) | 1,0 (14,7) | ||

| Flow @ min DP | lmin-1 (gal/min) | 4,0 (1,1) | 7,0 (1,9) | |

| Temperature | °C (°F) | 5 – 40 (41 – 104) All variants | ||

| Connection | 3/8″ BSP Male (G 3/8”) | |||

| Purge Gas* | Pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | |

| Light Duty | sl/min | 12 | ||

| Medium Duty | sl/min | 18 – 52 | ||

| Connection | Swagelok® Ø ¼” tube with olive | |||

| High Flow Purge/ Solvent Flush | Supply pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | |

| Control valve connection | Swagelok® Ø 3/8″ tube with olive | |||

| Filter connection | ½” NPT Male | |||

| Solvent connection | 3/8″ BSP Male (G 3/8″) | |||

| Mass | kg (lbs) | 305 (672) | 475 (1047) | |

| Noise (with suitable exhaust pipe) | dB(A) | < 64 | ||

| Operating Temperature | °C (°F) | 5 – 40 (41 – 104) | ||

| Exhaust Back Pressure (MAX) | mbar (psia) | 1400 (20) | ||

| System IP rating | Standard | 31 | ||

| Lubrication | Type | PFPE Drynert® 25/6 | ||

| Volume | l (gal) | 0,7 (0,2) | 1,4 (0,4) | |

| Monitoring & | Standard | Control | Front panel “Dashboard” | |

| Control | Serial – RS232 | |||

| Monitoring | Ethernet Webserver | |||

| Option | Control | Parallel – MCM MicroTIM | ||

| Control & Monitoring | Profibus DP | |||

| Pump Display Terminal (PDT) | ||||

| Monitoring | FabWorks® | |||

| *Pump combinations | Light duty | Shaft Seal Purge only | ||

| Medium duty | Shaft Seal Purge, High Vac Purge, Inlet Purge, variable Gas Ballast & Exhaust Purge (with Exhaust Pressure Sensor) | |||

| Medium duty + | As Medium duty, plus High Flow Purge / Solvent Flush | |||

(1) DP – Dry Pump

* Purge Gas information

Light duty: shaft seal purge only

Medium duty: Shaft seal purge, inlet purge, variable gas ballast & exhaust purge (with exhaust pressure sensor)

Medium duty plus: As Medium duty, plus High Flow Purge / Solvent Flush

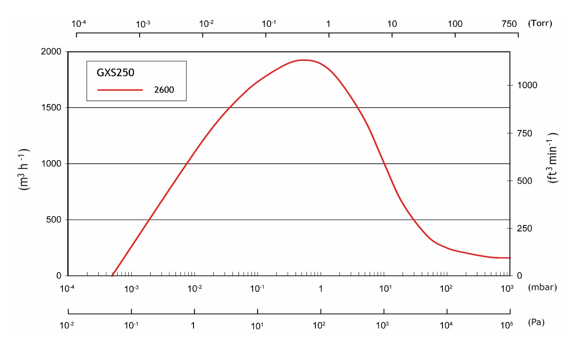

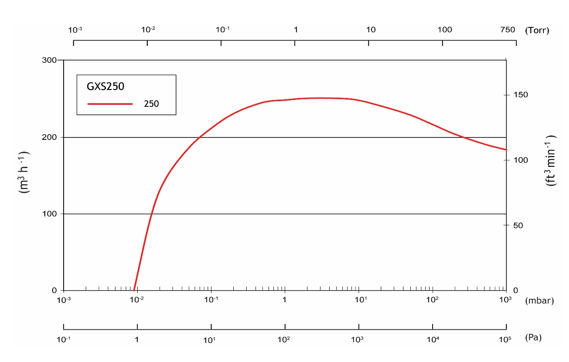

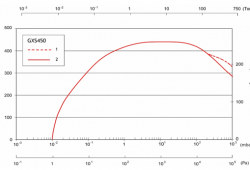

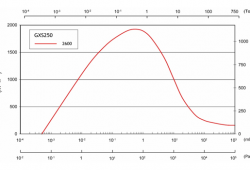

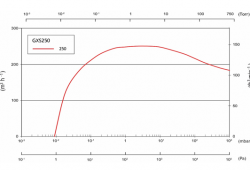

GXS250 Dry Pump

| Units | GXS250 | GXS250/2600 | ||

| Peak Pumping Speed | m3h-1 (cfm) | 250 (147) | 1900 (1118) | |

| Ultimate Pressure (without purge) | mbar (Torr) | 4 x 10-3 (3,0 x 10-3) | 5 x 10-4 (3,8 x 10-4) | |

| Full Load Power | @ ultimate pressure | kW (hp) | 4,0 (5,4) | 5,3 (7,1) |

| @ peak pumping load | kW (hp) | 9,0 (12,1) | 9,7 (13,0) | |

| Electrical | Supply options | High volt | 380 – 460V 3Ø 50/60Hz | |

| Low volt | 200 – 230V 3Ø 50/60Hz | |||

| Connection | High volt | Harting Han K 4/4-F | ||

| Low volt | ||||

| Vacuum Couplings | Inlet | ISO63 | ISO160 | |

| Exhaust | NW40 | |||

| Cooling Water | Supply pressure (max) | bar (psig) | 6,9 (100) | |

| DP(1) across pump (min) | bar (psig) | 1,0 (14,7) | ||

| Flow @ min DP | lmin-1 (gal/min) | 4,0 (1,1) | 7,0 (1,9) | |

| Temperature | °C (°F) | 5 – 40 (41 – 104) All variants | ||

| Connection | 3/8″ BSP Male (G 3/8”) | |||

| Purge Gas* | Pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | |

| Light Duty | sl/min | 12 | ||

| Medium Duty | sl/min | 18 – 52 | ||

| Connection | Swagelok® Ø ¼” tube with olive | |||

| High Flow Purge/ Solvent Flush | Supply pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | |

| Control valve connection | Swagelok® Ø 3/8″ tube with olive | |||

| Filter connection | ½” NPT Male | |||

| Solvent connection | 3/8″ BSP Male (G 3/8″) | |||

| Mass | kg (lbs) | 305 (672) | 515 (1035) | |

| Noise (with suitable exhaust pipe) | dB(A) | < 64 | ||

| Operating Temperature | °C (°F) | 5 – 40 (41 – 104) | ||

| Exhaust Back Pressure (MAX) | mbar (psia) | 1400 (20) | ||

| System IP rating | Standard | 31 | ||

| Lubrication | Type | PFPE Drynert® 25/6 | ||

| Volume | l (gal) | 0,7 (0,2) | 1,4 (0,4) | |

| Monitoring & | Standard | Control | Front panel “Dashboard” | |

| Control | Serial – RS232 | |||

| Monitoring | Ethernet Webserver | |||

| Option | Control | Parallel – MCM MicroTIM | ||

| Control & Monitoring | Profibus DP | |||

| Pump Display Terminal (PDT) | ||||

| Monitoring | FabWorks® | |||

| *Pump combinations | Light duty | Shaft Seal Purge only | ||

| Medium duty | Shaft Seal Purge, High Vac Purge, Inlet Purge, variable Gas Ballast & Exhaust Purge (with Exhaust Pressure Sensor) | |||

| Medium duty + | As Medium duty, plus High Flow Purge / Solvent Flush | |||

(1) DP – Dry Pump

* Purge Gas information

Light duty: shaft seal purge only

Medium duty: Shaft seal purge, inlet purge, variable gas ballast & exhaust purge (with exhaust pressure sensor)

Medium duty plus: As Medium duty, plus High Flow Purge / Solvent Flush

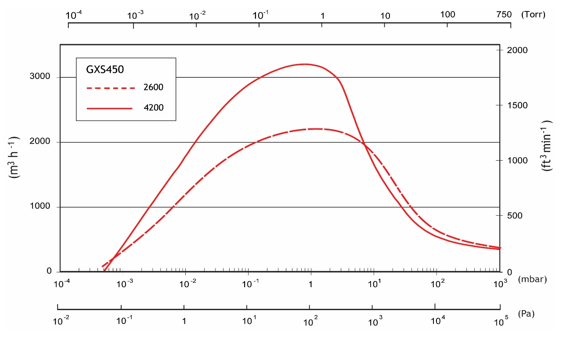

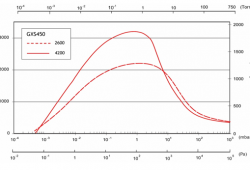

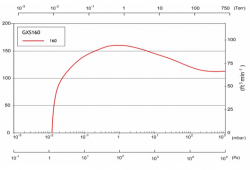

GXS450 Dry Pump

| Units | GXS450 | GXS450/2600 | GXS450/4200 | ||

| Peak Pumping Speed | m3h-1 (cfm) | 450 (265) | 2200 (1295) | 3026 (1781) | |

| Ultimate Pressure (without purge) | mbar (Torr) | 5 x 10-3 (3,8 x 10-3) | 5 x 10-4 (3,8 x 10-4) | ||

| Full Load Power | @ ultimate pressure | kW (hp) | 7,2 (9,6) | 8,8 (11,8) | 9,4 (12,6) |

| @ peak pumping load | 17,3 (23,2) | 20,0 (26,8) | 21,1 (28,3) | ||

| Electrical | Supply options | High volt | 380 – 460V 3Ø 50/60Hz | ||

| 200 – 230V 3Ø 50/60Hz | |||||

| Connection | Harting Han K 4/4-F | Harting Han 100A-F | |||

| Vacuum Couplings | Inlet | ISO100 | ISO160 | ||

| Exhaust | NW50 | ||||

| Cooling Water | Supply pressure (max) | bar (psig) | 6,9 (100) | ||

| DP(1) across pump (min) | 1 (15) | 1,5 (22) | |||

| Flow @ min DP | 6 (1,6) | 12 (3,2) | |||

| Temperature | 5 – 40 (41 – 104) All variants | ||||

| Connection | 1/2″ BSP Male (R 1/2”) | ||||

| Purge Gas* | Pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | ||

| Light Duty | 12 | ||||

| Medium Duty | 18 – 146 | ||||

| Connection | Swagelok® Ø ¼” tube with olive | ||||

| High Flow Purge/ Solvent Flush | Supply pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | ||

| Control valve connection | Swagelok® Ø 3/8″ tube with olive | ||||

| Filter connection | ½” NPT Female | ||||

| Solvent connection | 3/8″ BSP Male (G 3/8″) | ||||

| Mass | kg (lbs) | 640 (1411) | 860 (1996) | 868 (1914) | |

| Noise (with suitable exhaust pipe) | dB(A) | < 64 | |||

| Operating Temperature | °C (°F) | 5 – 40 (41 – 104) | |||

| Exhaust Back Pressure (MAX) | mbar (psia) | 1400 (20) | |||

| System IP rating | Standard | 31 | |||

| Lubrication | Type | PFPE Drynert® 25/6 | |||

| Volume | 1,8 (0,5) | 2,5 (0,7) | 3,6 (1,0) | ||

| Monitoring & | Standard | Control | Front panel “Dashboard” | ||

| Serial – RS232 | |||||

| Ethernet Webserver | |||||

| Option | Parallel – MCM MicroTIM | ||||

| Profibus DP | |||||

| Pump Display Terminal (PDT) | |||||

| FabWorks® | |||||

| *Pump combinations | Light duty | Shaft Seal Purge & High Vac Purge only | |||

| Medium duty | Shaft Seal Purge, High Vac Purge, Inlet Purge, variable Gas Ballast & Exhaust Purge (with Exhaust Pressure Sensor) | ||||

| Medium duty + | As Medium duty, plus High Flow Purge / Solvent Flush | ||||

(1) DP – Dry Pump

* Purge Gas information

Light duty: shaft seal purge only

Medium duty: Shaft seal purge, inlet purge, variable gas ballast & exhaust purge (with exhaust pressure sensor)

Medium duty plus: As Medium duty, plus High Flow Purge / Solvent Flush

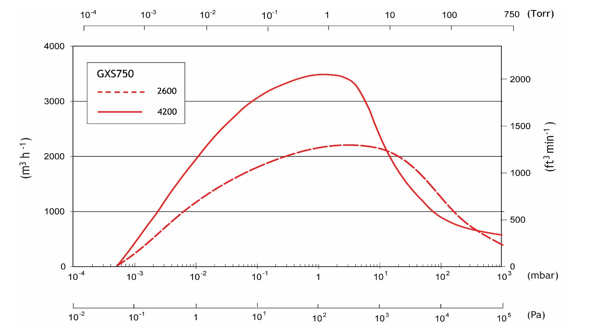

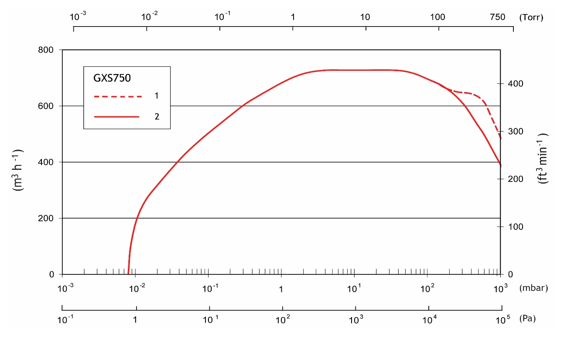

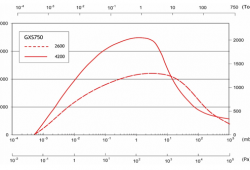

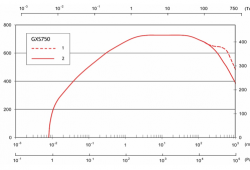

GXS750F Dry Pump

| Units | GXS750 | GXS750/2600 | GXS750/4200 | ||

| Peak Pumping Speed | m3h-1 (cfm) | 740 (436) | 2300 (1354) | 3450 (2031) | |

| Ultimate Pressure (without purge) | mbar (Torr) | 3 x 10-3 (2,3 x 10-3) | 5 x 10-4 (3,8 x 10-4) | ||

| Full Load Power | @ ultimate pressure | kW (hp) | 10,0 (13,4) | 11,1 (14,9) | 11,5 (15,4) |

| @ peak pumping load | kW (hp) | 37,0 (49,6) | 40,0 (53,6) | 40,0 (53,6) | |

| Electrical | Supply options | High volt | 380 – 460V 3Ø 50/60Hz | ||

| Low volt | 200 – 230V 3Ø 50/60Hz | ||||

| Connection | High volt | Harting Han 100A-F | |||

| Low volt | Harting Han 200A-F | ||||

| Vacuum Couplings | Inlet | ISO100 | ISO160 | ||

| Exhaust | NW50 | ||||

| Cooling Water | Supply pressure (max) | bar (psig) | 6,9 (100) | ||

| DP(1) across pump (min) | bar (psig) | 2 (29) | 2,5 (36) | ||

| Flow @ min DP | lmin-1 (gal/min) | 10 (2,6) | 12 (3,2) | ||

| Temperature | °C (°F) | 5 – 40 (41 – 104) High Volt variants | |||

| 5 – 30 (41 – 86) Low Volt variants | |||||

| Connection | 1/2″ BSP Male (R 1/2”) | ||||

| Purge Gas* | Pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | ||

| Light Duty | sl/min | 12 | |||

| Medium Duty | sl/min | 18 – 146 | |||

| Connection | Swagelok® Ø ¼” tube with olive | ||||

| High Flow Purge/ Solvent Flush | Supply pressure | bar (psig) | 2,5 – 6,9 (36 – 100) | ||

| Control valve connection | Swagelok® Ø 3/8″ tube with olive | ||||

| Filter connection | ½” NPT Female | ||||

| Solvent connection | 3/8″ BSP Male (G 3/8″) | ||||

| Mass | kg (lbs) | 640 (1411) | 908 (2002) | 953 (2101) | |

| Noise (with suitable exhaust pipe) | dB(A) | < 70 | |||

| Operating Temperature | °C (°F) | 5 – 40 (41 – 104) | |||

| Exhaust Back Pressure (MAX) | mbar (psia) | 1400 (20) | |||

| System IP rating | Standard | 31 | |||

| Lubrication | Type | PFPE Drynert® 25/6 | |||

| Volume | l (gal) | 2,4 (0,6) | 3,1 (0,8) | 4,2 (1,1) | |

| Monitoring & | Standard | Control | Front panel “Dashboard” | ||

| Control | Serial – RS232 | ||||

| Monitoring | Ethernet Webserver | ||||

| Option | Control | Parallel – MCM MicroTIM | |||

| Control & Monitoring | Profibus DP | ||||

| Pump Display Terminal (PDT) | |||||

| Monitoring | FabWorks® | ||||

| *Pump combinations | Light duty | Shaft Seal Purge & High Vac Purge only | |||

| Medium duty | Shaft Seal Purge, High Vac Purge, Inlet Purge, variable Gas Ballast & Exhaust Purge (with Exhaust Pressure Sensor) | ||||

| Medium duty + | As Medium duty, plus High Flow Purge / Solvent Flush | ||||

Application

• Metallurgy.

• Coating.

• Drying.

• Solar.

• Vacuum chamber evacuation.

Accessories

Pressure Indicator Assembly 90 deg M58808141

GXS N2 STD flow switch kit A50633000

Cooling water flow monitoring switch A50783000