TRIPLE ion-beam milling system EM TIC3X

Description

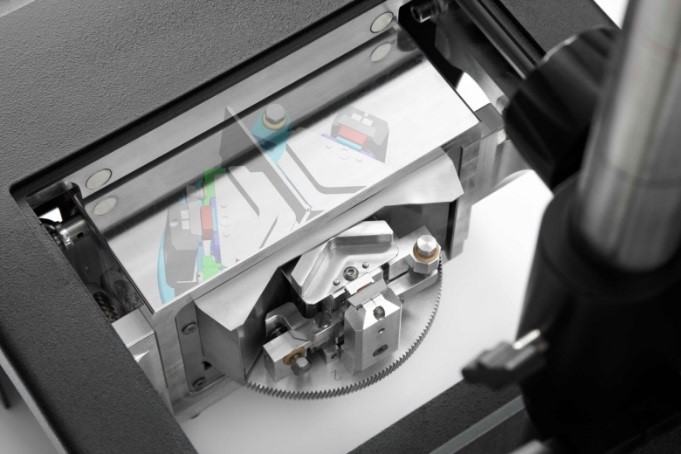

Leica EM TIC3X provides the largest cross-section area to offer the highest analyses yield. Unique features are the highest speed and largest uniform area for flat milling (ion beam polishing) technique to achieve reliable results fast. In addition, the device will ensure a fast workflow by using the synergy with the Leica EM TXP (mechanical preparation device), so the preparation time of the finished sample is minimized.

Specification

Leica EM TIC3X provides the largest cross section area to offer highest analyses yield. Unique features are the highest speed and largest uniform area for flat milling (ion beam polishing) technique to achieve reliable results fast. In addition, the device will ensure a fast workflow by using the synergy with the Leica EM TXP (mechanical preparation device), so the preparation time of the finished sample is minimized.

- Ion energy 1keV to 10keV

- Source current 0.5 to 4.5mA / 0.1mA stepsize (per ion source)

- Current density 10 mA / cm² (per ion source)

- Ion beam diameter: 0.8 mm (at 10 keV), 2.5 mm (at 2 keV)

- Cathode life time >350h for 8kV, 3.0mA

Accesories

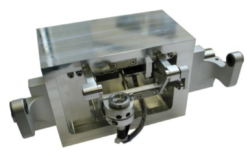

- STANDARD STAGE (sample size up to 50mm x 50mm x 5 to 10mm)

- COOLING STAGE (cooling the sample holder and mask; temperature range from +30 to –160°C +/– 5°C)

- MULTIPLE STAGE (three-position stage)

- ROTARY STAGE (max. sample size Ø 38mm / 12mm thick)

- Retrofitting with a VCT port for sample transfer in a vacuum or cryo application.