DSS2

Description

DSS2 is the extraction station for Cleanpart’ner particle trackers for small and medium-sized components. It allows the extraction of contamination on very small components to assess their level of cleanliness in accordance with current standards such as ISO 16232 and VDA19, among others.

Specification

• Extraction area: Width (mm): 507 / 600 max. Depth (mm): 459 Height (mm): 630 + 205

• Ovoid extraction enclosure to minimize particle retention, super polished mirror finish, Ra 0.02

• Fast and repeatable blank acquisition, value less than 150 µm, 100 µm repeatable as a minimum

• Integrated in the bottom of the sink, adjustable power of 400 W (optional)

• Automatic Wall flushing integrated into walls without risk of particles retention

• Full access to the extraction area (optional sliding window)

• Double air supply flow and exhaust air extraction, integrated in to the station (operator protection)

• Laminar air flow with HEPA filter 0,3 µm meet a class 5 max. according to ISO 14644

• Touch colour machine interface with functional and intuitive controls

• Designed and manufactured in our workshops

• Quality of finishes and choice of materials to avoid particle generation and retention

• Proven and reliable equipment

• EC fully compliant – Comply with the European Machinery Directives

• 2006 and Electromagnetic compatibility

• Two types of PLC available as standard: PRO-FACE or SIEMENS

• Pen flow rate: adjustable 5 L/mn max. – Walls flushing: 12 L/mn max.

• Rinsing pressure: 4,5 bar max.

• Useful volume tank: 40 litres

• Membrane holder: Ø 47 mm – optional cascade of 3 membranes

• Fluid filtration rate: 0,2 µm

• Accepted types of fluid: solvent or detergent (water base)

• Materials: 304L stainless-steel polished bowl – Painted steel for structure

• Fine textured powder paint

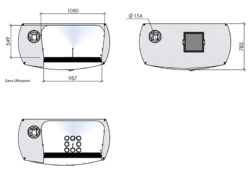

• Extraction connection: 154 mm outside

• Power consumption: 1700W max.

Accesories

• Solvent pen with different Ø

• Set of glasware for small parts

• Cascade membrane holder Ø47

• Plastic plate and sieve