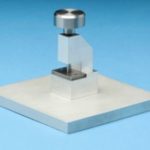

Model 200 Dimpling Grinder

Description

he Model 200 Dimpling Grinder is a state-of-the-art mechanical grinder for preparing electron microscopy samples. It is indispensable when ion milling is used for final specimen thinning. Once the specimen is prethinned by dimpling, ion milling must remove only a relatively small amount of material.

High-quality specimens for transmission electron microscopy need to be both rugged and have a large electron transparent area for analysis. Dimpling is a rapid technique that involves rotating both the grinding wheel and the specimen. This combination of motions produces a specimen with only its central area reduced to a thickness of a few microns.

The automated and versatile dimpling grinder can be used for flat grinding, dimpling, or polishing. The dimpling grinder features grinding rate control, a precise indication of specimen thickness, and an easy-to-use interface.

The specimen can be accurately positioned using an optical microscope with transmitted and/or reflected light. The final specimen thickness is readily programmed for accurate, unattended operation. The Model 200 accepts mounted specimens from the Model 160 Specimen Grinder.

Key Specifications

• Controlled thinning rate

• Precise

• Easy to use

• Automated operation

• Alignment microscope

Specification

Grinding control

Automated grinding rate control

Grinding force adjustable with micrometer counterweight

system

Independent control of grinding wheel and specimen

rotation speeds

Specimen stage

Precise specimen stage rotation

Magnetic mount allows easy specimen positioning

User interface

All program inputs via front panel keypad

Specimen thickness indicated on a liquid crystal display

Specimen illumination

Specimen observation in either transmitted or reflected light

Enclosure

Weight: 18 lb (8.2 kg)

Size: 8.2 in (208 mm) width x 6.5 in (165 mm) height x

13.5 in (343 mm) depth

Power requirements

110/220 V AC, 50/60 Hz, 375 W

Accesories

MODEL 130 Specimen Punch

Prepare high-quality disk specimens. A precision ground punch and die plate eliminate specimen stress and distortion. For convenient handling, a spring-loaded return plunger keeps the disk specimen on the die plate surface.

Available with or without a base and in standard sizes of 1.0 mm, 2.3 mm, and 3.0 mm. Other sizes available upon request.

Model 160 Specimen Grinder

For transmission electron microscopy, the quality of the initial disk determines the quality of the final specimen. The Model 160 Specimen Grinder is an accurate and dependable tool for mechanically prethinning specimens. It produces specimens of uniform thickness and parallel sides within minutes. During the grinding process, a graduated scale allows the specimen thickness to be controlled easily and precisely. If further thinning via dimpling is required, the platen containing the specimen is simply ejected from the specimen grinder and installed directly into the Model 200 Dimpling Grinder.

Consumables

https://micro-shop.pl/kategoria-produktu/tem/siatki-z-pokryciem-carbon/

For more supplies, please visit our online store Micro-Shop.