NANO – Robotics Solutions for Electron Microscopes

Description

Integrated nanoprobing solutions for SEM and FIB. Bring probe tips in contact with semiconductor chips, measure the electrical characteristics of integrated components, localize defects and isolate structures.

Imina Technologies’ NANO solutions are turnkey for electrical characterization of microelectronic devices, in situ semiconductor failure analysis and manipulation of single structures in SEM and FIB chambers. Fully controlled from Precisio™ software suite, comprehensive workflows provide operator assistance from setting up the system, to landing probe tips on the device under test, acquiring and processing measurements and reporting.

Up to 8 miBot™ nanoprobers can be delivered with various configurations and options to adapt to application specific requirements and equipment setups.

The compact and light platforms for the robots are compatible with any electron microscope and can either be mounted on the SEM sample positioning stage, or be loaded via the SEM load-lock.

The compatibility with high resolution imaging using magnetic lenses enables the operator to perform nanoprobing experiments with the most advanced scanning electron microscopes on the market and take advantage of the highest resolution imaging capabilities, even at accelerating voltages below 0.5 kV.

As the whole platform and robots can be tilted, in situ FIB circuit editing and nanoprobing can be performed simultaneously providing faster and more accurate failure analysis results.

No permanent modification of the chamber is required and the installation and removal of the system only takes a few minutes. This avoids to dedicate an SEM for nanoprobing. Also, various extra accessories exist to easily operate the main components of a NANO solution under optical microscopes such as probe stations and inspection tools, increasing the value of your investment.

Applications:

Semiconductor characterization

─ I/V curves of single transistors

─ Bit cell memories characterization

─ IC attacks for cybersecurity, reverse engineering

Failure Analysis (FA)

─ EBIC: Electron Beam Induced Current

Defects localization at p/n junction

─ EBAC/RCI: Electron Beam Absorbed Current

Shorts/Opens detection at metal lines

Materials characterization and nano-manipulation

─ 4-point probing on single structures

─ Thin-film characterization

─ Single structure isolation (nanowires, particles, etc), TEM sample preparation

Specification

Degrees of freedom

4 independently driven (X,Y,R,Z) per probe

Dimensions & weight

Body: 20.5 x 20.5 x 13.6 mm3

Arm: 8.3 mm (without tool)

Weight: 12 g (without tool)

Max. positioning resolution:

Motion modes: coarse (stepping) and fine (scanning)

Stepping: 50 nm (X, Y), 120 nm (Z)

Scanning: 1.5 nm (X, Y), 3.5 nm (Z)

Motion range

Stepping (XY,R,Z): 20 x 20 mm2 , ± 180°, 42°

Scanning (X Y Z): 440 x 250 x 780 nm3

Note: in stepping, actual X, Y, R range are limited by the size and shape of the stage where the miBot moves, and the length of the driving cable.

Speed

X and Y: up to 2.5 mm.s-1 Z: up to 150 mrad.s-1

Forces & torques

X and Y: push: 0.3 N Z: lift: 0.7 mNm (5 g)

hold: 0.2 N hold: 0.9 mNm (6 g)

Tilt angle Holding position up to 55°

Tool holders

Range of holders for probes and optical fibers

Accesories

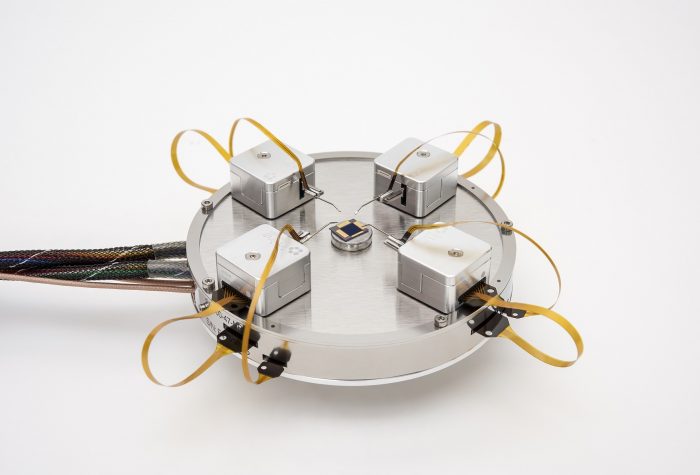

Stage mounted platform 4-Bot

•Compact design (diameter: 100 mm)

• Up to 4 independently driven miBot™ nanoprobers

•Sample size up to approx. 1”

Stage mounted platform 8-Bot

•Wide design (diameter: 125 mm)

•Up to 8 independently driven miBot™ nanoprobers

•Sample size up to approx. 2”

Load-lock platform 8-Bot

•Wide design (diameter: 110 mm)

•Up to 8 independently driven miBot™ nanoprobers

•Sample size up to approx. 1.5”

• Typical airlock door inner dimensions:

150 (w) x 45 (h) mm

Special platform integrations

•For large/thick samples (e.g. packaged chips)

• With heating/cooling sample stages

•Custom chamber set-ups (e.g port-mounted)

Active sample holder:

•Manual sample height adjustment (8 mm range)

•User defin ed specimen biasing

Sample positioning XYZ sub-stage

• Move the sample independently from the probes

in X, Y, Z directions (travel range: 5 mm (X, Y),

330 um (Z); max. resolution: 2 nm (X, Y), 7 nm (Z))

• Reduce probes landing time and accelerate multiple

device characterization

•User defined specimen biasing

Additional SEM integration kits

Install your nanoprobing system in minutes and

operate in any of your microscopes by preinstalling

the interface parts on the different chambers.

EBIC acquisition system

High performance external current amplifier and

SEM image acquisition system for quantitative

EBIC capabilities

EBIC & EBAC/RCI acquisition system

Best in class in situ and ex situ preamplifiers

combined with integrated scan generator and

SEM image acquisition system for quantitative

EBIC and low noise EBAC/RCI analyses