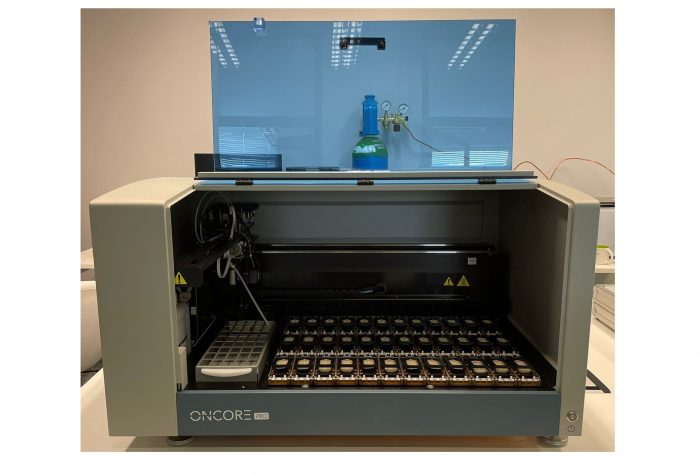

Automatic slide staining system

Description

The ONCORE PRO automated slide staining system is a compact and convenient tabletop unit used for IHC and in situ hybridization procedures. Automation includes slide pre-drying, deparaffinization, antigen uncovering and probe/antibody inoculation and detection.

The system provides convenience, flexibility and ease of use. The interface is intuitive, requiring minimal interaction. The system also uses 2D matrix labels, for labeling patient specimens, greatly reducing patient identification errors. Independently programmable slide positions allow different protocols to be performed in a single run.

The ONCORE Pro uses unique reaction modules that place slides between a heated platform and a chamber containing reagents. These chambers provide gentle mixing during reagent incubation to maximize staining intensity. Reagent vials are identified with RFID technology that stores important information, including name, lot number, expiration date and number of tests, minimizing user error by tracking reagent volumes in real time.

IHC reagents and antibodies are designed to provide exceptional staining quality, as well as the ability to use primary antibodies from other manufacturers. The ONCORE PRO antibody menu has been developed for a wide range of laboratories and tissue types, making it ideal for clinical applications. The ability to perform multiplex IHC reactions allows, reduce the number of slides and cut labor costs by 50%.

Technical specification

| Capacity | 36 slides | |

| Protection against evaporation | Chamber with side safety clips, reagent dispensing and waste extraction chimney | |

| Reagent station | One station for up to 40 reagents | |

| Temperature range of antigen exposure | From room temperature to 103°C; maximum 110°C | |

| Multidispensing needle capacity | 5mL | |

| Volume of reagents dispensed | Antibody: 130uL; Reagent: from 65 minmal to 400 μl maximum | |

| Volume of deparaffinization buffers consumed | DS1 – 240uL i DS2 – 200uL | |

| Containers and waste | Flushing buffer (2L), Container for hazardous waste (4L) and non-hazardous waste (4L) | |

| Control unit | One device per computer | |

| Weight of the device | 125lbs (57 kg) | |

| Dimensions of the device | 36.5 in x 22 in x 24 in / 93 cm x 56 cm x 61 cm (with door closed) 36.5 in x 36 in x 24 in / 93 cm x 91 cm x 61 cm (with door open) | |

| Electrical requirements | 120V 110/120V (±10%) 60Hz (±2Hz) 850 watts 220V 220/240V (±10%) 50Hz (±2Hz) 850 watts | |

| Voltage tolerance | 100 to 240 AC | |

| Noise level | Minimum operating noise 47.0 dBA, maximum operating noise 69.6 dBA | |

| Reports generated | Preparation barcode, patient information, course of staining | |

| LIS | Connection to HL7 server and connection to MSSQL database | |