Turbomolecular vacuum pump with magnetic bearing STP

Description

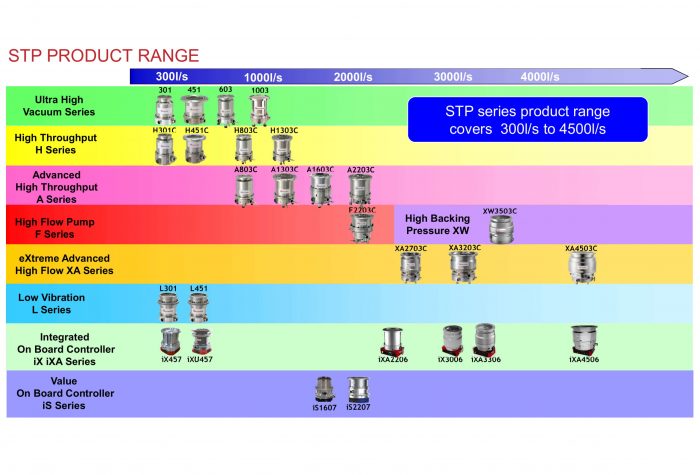

STP Series has four main product groups:

– Integrated Controller Series

The integrated controller series can be fully interfaced with advanced controllers to operate on a wide range of applications and processes. It eliminates the need for a conventional, rack-mounted controller and interconnecting cables. The fully integrated product offers easy installation and small footprint as an all-in-one solution for all application tools.

– Ultra High Vacuum Series

The multistage pure bladed rotors in the UHV pumps provide the high vacuums required for clear beamlines on CD SEM machines, mass spectrometers and ion implanters. They provide optimum pumping

performance with excellent light gas compression ratios.

– Ultra High Vacuum Low Vibration Series

The low vibration series has been designed to meet the low vibration requirements of advanced spectroscopy and metrology tools. It provides the advantage of having the vibration system built into the pump body.

– High Throughput Series

The high throughput pumps incorporate a Holweck drag stage that increases the pumps throughput at low pressure. Their advanced rotor design combined with selection of the best materials has allowed the creation of the next generation of high throughput turbo pump inside the same footprint as many of the existing models. The range contains pumps with throughput speeds from 300 l s-1 to 4500 l s-1.

Specification

• Excellent pumping performance with speeds from 300 to 4500l/s covers all potential turbo pump applications.

• Advanced material and designs provide class leading performance in all classes.

• Automatic Balancing System (ABS) and Automatic Vibration Reduction (AVR) offer very low noise and vibration.

• Magnetic bearing system will allow installation in any angle.

• Field proven reliability.

• Low cost of ownership.

• Wide range of remote signal available- I/O Remote,RS232, RS485, Profibus (optional).

• RoHS Compliant and UL approved.

Applications

• Metal/Oxide/Silicon Etch.

• Ion Implant.

• Film deposition CVD.

• Metrology and analytical instruments.

• Load lock and transfer chambers.

• PVD coating system.

• R&D applications.

• Heat treatment.