XDS

Description

XDS scroll pumps have become industry standard when dry pumping is essential, proving to be a robust and clean vacuum pump solution in a range of applications and processes.

The XDS35i pump has an innovative bearing shield that isolates the vacuum environment from all forms of lubricant, making it not only lubricant-free but hermetically sealed. XDS35iNGB variant has had the gas ballast feature removed for applications such as rare gas recirculation and gas recovery.

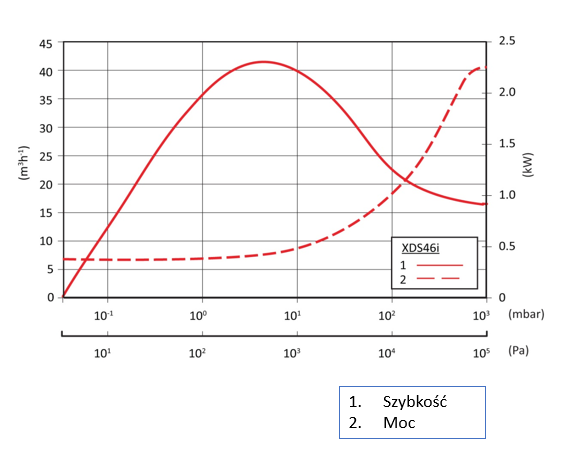

The XDS46i shares many of the same features of the XDS35i but with a peak speed of 40 m3h-1. The pump has been optimised for maximum pumping speed at inlet pressures between 1 mbar and 10 mbar, making it ideally suited for LCMS and ICPMS applications requiring higher pumping speeds.

The C variant has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications using corrosive substances. The C version is fitted with Chemraz® internal valve pads and stainless steel exhaust port.

Specification

• Lubricant-free within the vacuum envelope and hermetically sealed means a totally clean and dry vacuum to prevent cross contamination.

• No atmosphere to vacuum shaft seals means bearings are completely isolated, this prevents process attack and enable the bearings to run cooler and last longer.

• No oil to change eliminating cost of contaminated oil disposal.

• Simple single sided scroll design allows maintenance to be done in minutes for low cost of ownership and maximum up‑time.

• Inverter drive for consistent pumping speeds worldwide.

• Pump range includes 35 and 40 m3h-1.

Applications

• Automotive; brake line and air conditioning evacuation.

• Backing turbomolecular pumps.

• Chemical applications including gel dryers and solvent recovery.

• Coating systems.

• High energy physics.

• Mass spectrometry.

XDS35i - small dry pump Scroll type

| XDS35i | XDS35i Enhanced | ||

| Peak pumping speed | m3h-1(cfm) | 35 (21) | |

| Ultimate vacuum (1) | mbar (Torr) | 0,01 (0,008) | 0,03 (0,02) |

| Ultimate vacuum with gas ballast 1 | mbar (Torr) | 0,02 (0,015) | 0,04 (0,03) |

| Ultimate vacuum with gas ballast 2 | mbar (Torr) | < 10 (7,5) | |

| Max inlet pressure for water vapour | mbar (Torr) | 35 (23) | |

| Water vapour handling capacity GBII | gh-1 | 240 | |

| Maximum continuous inlet pressure | mbar a (Torr a) | 40 (30)(2) | 1000 (760) * |

| Maximum gas ballast/purge pressure | bar gauge (psig) | 0,5 (7) | |

| Motor data | |||

| Supply voltage | V | 100 – 120 / 200 – 240 (+/- 10%) | |

| Supply frequency | Hz | 50 / 60 | |

| Nominal rotation speed | rpm | 1750 | |

| Power at ultimate | W | 440 | |

| Motor power | W | 520 | |

| Power connector | IEC | EN60320 C19 | |

| Recommended fuse, 230 V (115 V) | A | 16 (3) (15) | |

| Physical data | |||

| Weight | kg (lb) | 48 (105) | |

| Inlet connection | NW40 | ||

| Exhaust connection | NW25 | ||

| Noise level at ultimate | dB(A) | 57 | |

| Vibration at inlet flange | mms-1 (rms) | < 4,5 | |

| Leak tightness (static) | mbar ls-1 | < 1 x 10-6 | |

| Operating temperature range | °C (°F) | 5 – 40 (41 – 104) | |

* Use at higher inlet pressure speeds up tip seal wear

(1) measured as total pressure

(2) These pumps are designed to pump down from atmospheric pressure, but prolonged operation at inlet pressures higher than specified may reduce bearing life.

(3) for UK 240 V use 13 A fuse

XDS46i - small dry pump Scroll type

| Displacement 50 or 60Hz | 60 m3h-1 / 35 ft3min-1 |

| Peak pumping speed 50 or 60Hz | 40 m3h-1 / 23,5 ft3min-1 |

| Ultimate vacuum (Total pressure) | 5 x 10-2 mbar / 4 x 10-2 Torr |

| Max continuous inlet pressure | 40 mbar / 30 Torr |

| Max continuous outlet pressure | 0,2 bar gauge / 2,9 psig |

| Max allowed inlet and GB pressure | 0,5 bar gauge / 7 psig |

| Motor power | 0,52 kW |

| Power connector | IEC EN60320 C19 |

| Nominal rotation speed | 1750 rpm |

| Weight | 48 kg / 105 lb |

| Inlet flange | NW40 |

| Exhaust flange | NW25 |

| Noise level | 55,4 dB (A) |

| Vibration | < 4,5mms -1 (rms) |

| Leak tightness (static) | < 1 x 10-6 mbar ls-1 |

| Operating temperature range | 10 – 40 °C / 50 – 104 °F |