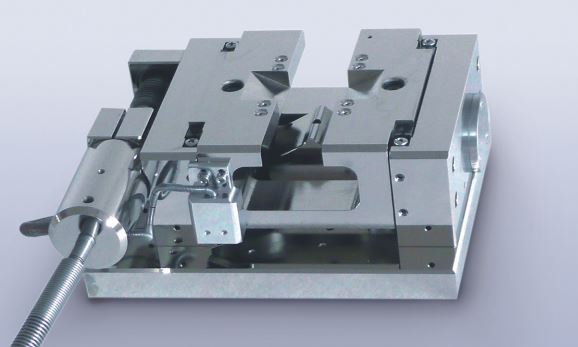

Bending Module 200 to 5000 N For 3- and 4-Point-Bending (Top view)

Description

This deformation device was originally designed to fit underneath the cantilever of an AFM.It is manufactured high-vacuum compatible, so you may also use it in the SEM. Changing from a 3-point bending to 4-point bending is a matter of a few seconds, just exchanging the “anvil” on which the specimen rests in center. The specimens should be 35 to 50 mm long, no wider than 10 mm, and up to 4 mm thick. The design is based upon two important thoughts: the whole device is extremely rigid, therefore almost no intrinsic flexure is detectable. Another advantage is the ultra-fine movement resolution of the load frame. Both these features are important with very brittle specimens, such as ceramics: after the finest initial cracks have formed, the specimen will not fly apart spontaneously. The bending process can be continued slowly, with extraordinary well defined load increase. The area of interest always remains stationary, so that – if at all – only minimal corrections need to be done ( in 4-point bending, the specimen flexes forward a few microns, in 3-point bending it remains perfectly stationary in the center area, throughout the entire experiment). The displacement speed range covers 0.2 to 20 µm/sec

Applications:

Static or dynamic observations of surface changes under controlled mechanical load; crack growth, delamination phenomena, formation of slip planes etc. Metals, ceramics, glass, ceramic bulk materials or layers, galvanic coating, soldered or welded joints, minerals, wood, organic materials

Specification

Load Ranges:

200 N, 500 N, 1000 N, 2000 N, 5’000 N load cells vailable. Others upon request.

Specimen dimensions (maximum sizes): 50 mm x 10 mm x 4 mm.

Deformation speed range: 02. to 20 µm/sec. Other speeds upon request.

Displacement range: 0 to 5 mm per experiment.

Electrical connection: 220 or 110 VAC.

Dimensions in mm (width/length/height): 100 mm (170 with heavy duty motor) x 130 mm x 55 mm

Accesories

Choice between manual controller (Starter system), and microprocessor controller (DDS-3) with interface and software (MDS) for PC-operation.