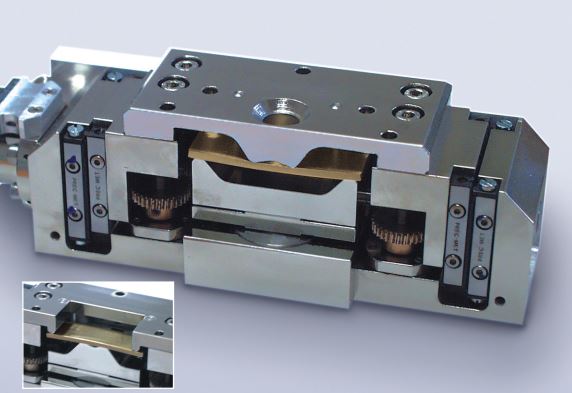

200 N Bending Module for 3- and 4-Point Bending Experiments

Description

Bending Module for “top- & side-view” without specimen exchange. This device is designed for use with SEM, AFM or optical microscopes. Within a few minutes, bending anvils are exchanged to allow 3-point or 4-point bending, or to change from convex to koncave and vice versa. To change observation direction, the module can be tilted (rotated) by 90°, even the specimen is under load. The mechanical design is made in a way that the region of interes (ROI) remains in focus during the experiment. Deformation speed range is 0.2 to 20 µm / sec. Other speeds on request

Applications:

Static or dynamic observations of surface changes under controlled mechanical load, crack growth, delaminating phenomenae, formation of glide planes etc. Metals, ceramics, glass, ceramic bulk materials or layers, galvanic coatings, soldered or welded joints, minerals, wood, organic materials. This materials testing, device fits most of today’s SEM specimen stages. Three small standoffs allow to place it under a light microscope. It was designed primarily for the use under a Nanoscope III, but small attachments allow the use of stand-alone AFMs. There is also enough clearance for experiments under a scanning acoustic microscope (SAM).

Specification

Load ranges: from 0 … 200N

Specimen dimensions (maximum sizes): 48 x 10 x 4 mm

Deformation speed range: 0.5 to 20 µm/sec.

Bending displacement range: 0 to 5 mm per experiment; the displacement gauge plunger can be

zeroed or re-zeroed over almost a centimeter

Electrical connection: 220 or 110 V AC.

Dimensions in mm (width/height/length): 40 x 40 x 180 mm

Accesories

Choice between manual controller (Starter system), and microprocessor controller (DDS-3) with interface and software (MDS) for PC-operation.