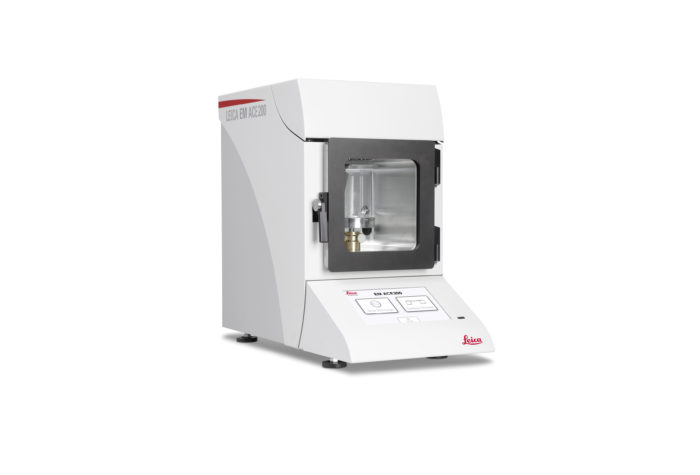

Low vacuum coater EM ACE 200

Description

The Leica EM ACE200 low-vacuum coating system is a precision device used in electron microscopy to obtain a conductive metal or carbon layer on the sample to be imaged.

Using the quartz thickness measurement (QSG), we have the ability to accurately measure the thickness of applied coating layer.

Specification

• Easily replaceable head for sputter coater or carbon from carbon thread

• different types of stages

• optional: glow discharge module for TEM grids hydrophilization

• stainless steel vacuum chamber

• removable chamber door, with large, replaceable and safe window

• automatic shutter

• intuitive touch screen for process control

• triple security system

• efficient rotary vane pump with oil vapor filter to protect against contamination in the absence of an exhaust gas outlet connection.

Accesories

- Quartz crystal for measuring the thickness of the layer (later update possible)

- Glow Discharge option for EM ACE200 (no later upgrade possible)

- Standard, manual stage (for 18 standard SEM 1/2 ”stubs, height adjustable).

- Rotating stage (integrated drive motor, height adjustable, easily exchangeable with manual stage, holding 18 standard stubs, fully integrated)

Ø Stolik na szkiełka, o wym. 76 mm x 26 mm.

- Table for Glass Slides

Exchangeable table (Ø 80 mm) with recess to hold a glassslide (76 x 26 mm)

- Planetary drive stage,

For uniform coatings of highly fissured specimen surfaces, integrated drive motor, easily exchangeable with manual stage, 30° pre-tilted, 4 planets with pin holes (ø 3,2mm) capable of holding 4 standard stubs each, fully integrated