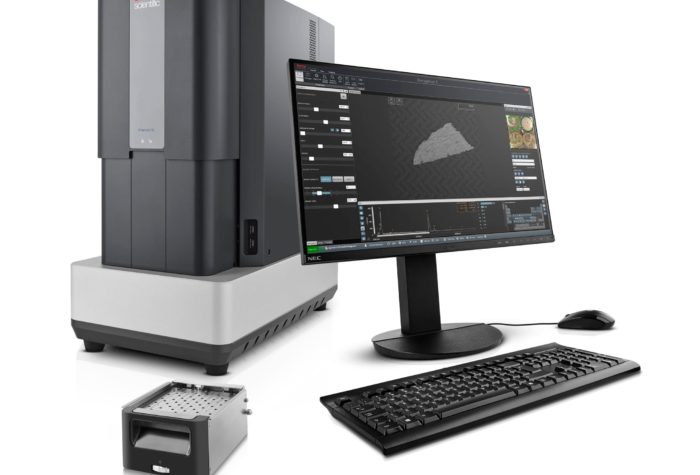

Phenom ParticleX TC

Description

Particle X is a stand-alone dedicated interface that works with the PhenomXL microscope to allow technical cleanliness testing against ISO 16232 and VDA19 standards.

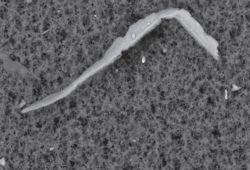

Particle X, by combining the capabilities of the Phenom XL microscope and a dedicated workstation, is able to quickly and incredibly accurately examine particles extracted from components manufactured in the automotive industry. The size of the tested particles ranges from 500nm to 3mm, which gives a huge field of action in terms of testing contaminants and eliminating them in the process of production, transportation or packaging ensuring the best possible parameters of technical purity. The extracted particles are examined on standardized 47mm filters widely used in technical purity analysis.

The presence of the EDS analyzer provides us with information about the elemental composition of contaminants, thanks to personalized algorithms, the Particle X interface is able to categorize the found particles from the appropriate groups of materials, e.g. metal alloys, ceramics, metal oxides as well as specific alloys that may come from different sources of contamination – the machine milling or cutting the part, the machine tool or the metal alloy coming from the cleaned part. It is an invaluable aid in analyzing sources of contamination and eliminating them quickly from any manufacturing process.

The Phenom ParticleX scanning microscope is also ideal for standard SEM imaging where we can observe and study the structure of samples. After a very simple disassembly of the holder for the septa, we get an area of 100mm x 100mm x 65mm H, which allows us to examine large samples. After taking the image, we can save it in JPEG, TIFF, BMP formats.

The Particle X interface after purity testing has the ability to generate reports in accordance with ISO 16232 and VDA19 standards. Depending on the customer’s requirements, the reports can be edited and tailored specifically to the customer’s requirements.

Specification

- Easy-to-use, intuitive user interface standardized against VDA 19.1 and ISO 16232

- Time required for image acquisition: Optical: 5 seconds Electron: 60 seconds

- Maximum sample dimensions: 100mm x 100mm (65mm high) or 4 47mm filters

- Magnification: from 80 to 100,000x

- Extremely easy navigation of the sample to the point of interest

- Presence of CCD camera which gives perfect correlation between optical and electron images

- Long life of CeB6 electron source (average of 1,500 hours)

- Electron source optimized for high resolution capability – 14nm

- CeB6 cathode operating with accelerating voltages of 5kV, 10kV, 15kV and 20kV

- Image storage formats: TIFF JPEG BMP

- Microscope equipped with EDS for qualitative study of impurities on the filter

Accessories

- SED detector

- Cartridges for metallographic specimens

- 3D image reconstruction software

- PoroMetric software

- FiberMetric software

- Mapping and EDS linear analysis software

Consumables

Po więcej materiałów eksploatacyjnych zapraszamy do naszego sklepu internetowego Micro-Shop.