Conspector

Description

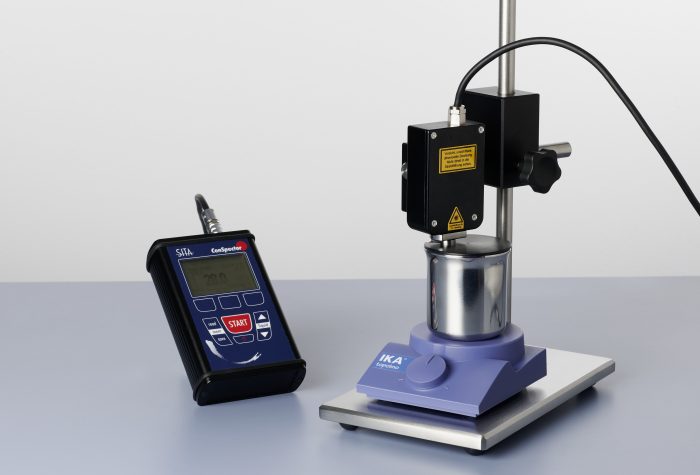

The SITA ConSpector controls the contamination level in cleaning and rinsing baths. An increasing contamination level causes a decreasing cleaning power. A high parts cleanliness despite of an optimal cleaning agent concentration cannot be guaranteed anymore if the bath is contaminated e.g. due to oils or greases.

The light guide rod at the sensor head of the measuring device is immerged in to the sample to be measured. The measurement starts at the touch of one button. The contamination level is displayed within a few seconds. Based on this measuring result, an optimal point of time for bath care actions or preparation of a fresh cleaning solution can be determined.

Failures of treatment measures can be quickly indentified due to continuous bath replenishment. For an easy operation, the measuring value is compared to an individually determined limit value and when exceeding an alarm signal is sent out by the device.

Controlling the bath contamination ensures a high cleaning quality and thus high parts cleanliness for processes in the field of surface coating and surface treatment. Cleaning bath contamination is reproducibly detected due to the fluorescence measurement. Controlling the contamination level allows reliable and efficient process management.

Measuring principle

The SITA ConSpector detects the bath contamination such as oils and greases through their fluorescence which is excited by UV light of an LED in the sensor head.

The UV light or fluorescence light is lead into the liquid by a light guide rod at the sensor head. A photodiode in the sensor head measures the fluorescence intensity. A high bath contamination leads to a high measuring value.

Application

Removing contamination off cleaning and rinsing bath in the industrial part cleaning industry ensures a long bath operation time and high parts cleanliness. The SITA ConSpector can measure the bath contamination in cleaning and rinsing baths at the plant or in the laboratory. The measuring result is available within a few seconds.

Sudden process disturbances such as the breakdown of the filter unit or a high increase of the contamination level in the bath can be immediately identified and resolved at the same time. Cleaning bath treatment measures can be carried out and controlled according to the application. The cleaning process can be carried out within allowed limit values leading to a reliable cleaning result. Controlling the rinsing steps with regard to the carry-over effect of contamination or cleaning chemicals avoids a further contamination of parts.

Specification

Contamination level / Fluorescence intensity

- Measuring range: 1…40.000 / (1 … 40.000) RFU*

- Max. measuring deviation: 0.5 % of measuring range

Liquid temperature

- Measuring range: (0…100) °C

- Max. measuring deviation: 0,5%

Current Supply

- Mains adapter: 5 V/500 mA (USB)

- Battery (Lion, integrated): 3,6 V/1950 mAh

- Max. power consumption: ca. 2,5 W

- Excitation diode 365 nm, max. 150 mW

Interface, Display, Memory

- USB interface: Data transfer, power supply & charging of battery

- Display: LCD, 128 x 64 Pixel, illuminated

- Memory permanent: measuring parameter / data 255 profiles, 8191 measuring values per profile

Ambient conditions

- Acceptable ambient temperature (storage / operation):(-20…60) °C / (10…50) °C

- acceptable ambient conditions: rel. humidity< 70 %, air pressure(300…1060) hPa

Housing, Dimensios, Weight

- Housing: Aluminium, IP 51

- Dimensions (WxHxD)

- Basic Unit: 129x82x48 in mm

- Sensor head: 142x50x30 in mm

- Weight of instrument 560 g

* RFU – Relative Fluorescence Unit of SITA-Fluorescence standard