System Quantax Xtrace Micro-XRF

Description

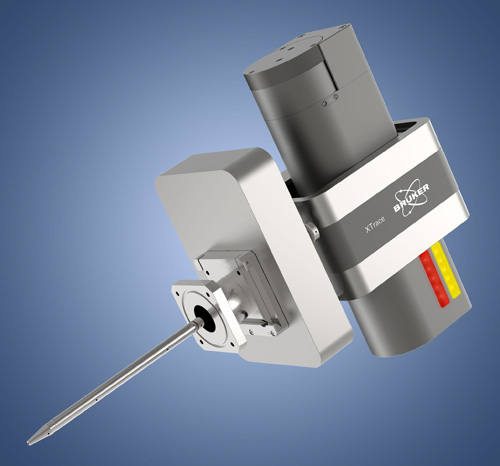

XTrace is a micro-spot X-ray source for attachment to almost any SEM with a free inclined port on the specimen chamber. It adds the capabilities of a complete micro-XRF spectrometer to the microscope. Limits of detection are improved 20 to 50-fold in the mid to heavy element range. Additionally, larger sample volumes become accessible as X-rays have a higher information depth than electrons.

The use of polycapillary X-ray optics allows the generation of high fluorescence intensities on very small sample areas. The X-ray optics collect tube radiation from a large solid angle and concentrates the X-rays on spots down to 35 micrometers in diameter for Mo-K radiation.

The generated X-ray fluorescence spectrum is measured with the attached XFlash® silicon drift detector, belonging to the QUANTAX EDS* system. The use of an XFlash® SDD gives excellent energy resolution, as determined by the detector specifications. Count rates of about 40 kcps can be achieved in the analysis of metals, using a 30 mm² active area detector.

The high intensity produced by the polycapillary optics and the reduced spectral background of X-ray excitation leads to an enhanced sensitivity for trace elements. The improvement is approximately 20 to 50 times compared to electron excitation. Also, because X-ray excitation is more efficient for higher-Z elements, detection limits down to 10 ppm can be achieved. This makes XTrace most interesting for the trace analysis of heavy elements.

QUANTAX EDS and XTrace offer the possibility of a combined micro-XRF and EDS quantification under a single user interface providing optimum results that are better than the results for each method alone.

Specification

Parameters:

Sample types : Solids, particles

Excitation :High brilliance X-ray tube with polycapillary X-ray optics

Excitation parameter:

Target material: Rh, optional Mo, W

Tube parameters: 50 kV, 600 µA (maximum 30 W, depending on X-ray tube)

Spot size: Less than 40 µm for Mo K

Polycapillary optics length: 400 mm

Filters: Up to 3 primary X-ray beam filters, standard configuration100 µm Al, 20 µm Ti, 10 µm Ni (other filters according tocustomer requirements possible)

Detection: XFlash® silicon drift detector*

Instrument control: no additional PC required, QUANTAX EDS PC can be used (recommended)*

Instrument software: Bruker ESPRIT

Instrument control functions: Complete control of tube parameters and filters

Spectra evaluation:XRF peak identification, artifact and background correction, peak area calculation, standardless quantification, combined XRF and EDS quantification, layer analysis

Distribution analysis: HyperMap capability (Hyperspectral database)

Result presentation: Quantification results, statistical evaluation, element distribution (line scan, mapping)

Power requirements: 100 – 240 VAC (1P), 50/60 Hz

Dimensions: 300 mm x 250 mm x 140 mm

Weight: 11 kg

Quality and safety: ISO 9001:2008, CE certified

Fully radiation protected system, radiation < 1 µSv/h

*XTrace requires a pre-installed QUANTAX energy-dispersive X-ray spectrometer

(EDS), consisting of XFlash® silicon drift detector, SVE signal processing unit and

Accessories

XMETHOD Layer – Coating Thickness for XTrace

Micro-XRF is a common used non-destructive analytical method for measuring the film thickness of different kinds of samples without any sample preparation. Additionally, the composition of the layer can be determined at the same time. Examples of such applications are: connector pins or solder bumps on PCB boards, lead frames and chip carriers, coatings on solar cells or even coatings that are used as corrosion protection for different kinds of materials. Both, the non-destructive operation of the method and the ability of X-rays to penetrate into the sample and obtain information on the material beneath the surface make this method attractive for the thickness and composition analysis of single and multiple layers.