Vacuum pumps CDX1000

Description

Edwards CDX1000 represents the latest generation of dry pump technology. The CDX1000 is a double-ended screw mechanism for the chemical process, pharmaceutical and petrochemical industries. This innovative technology leverages Edwards latest manufacturing and design philosophies. The CDX1000 is suited to larger processes where repeatability and reliability are key. Technologies and manufacturing techniques have been carefully selected to produce a robust, high performance machine that is simple to operate and maintain.

Specification

• Performance

— Continuous from atmosphere to ultimate.

— Excellent temperature control.

— Large liquid slug capability.

• Environment

— No effluent generated.

— Dry running mechanism.

— Efficient solvent recovery.

— Low power.

• Maintenance

— On-site seal and bearing change.

— Flushable with water, solvent or steam.

— Low rotational speed.

— Cooled and filtered oil.

— Integral accessory modules.

• Simplicity

— Low parts count.

— Balanced rotor design.

— No compression plate.

— Industry standard motors.

Technical parameters

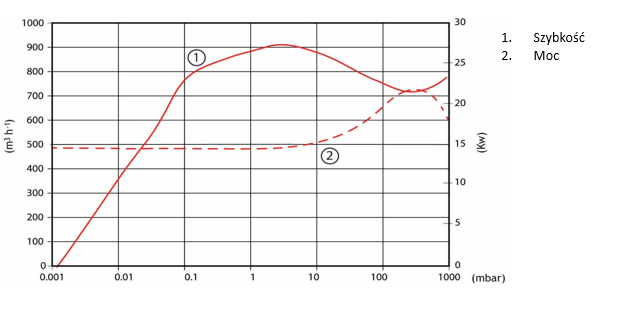

| Maximum pumping speed | 900 m3h-1 |

| 530 ft3min-1 | |

| Capacity at 10 mbar (7.5 Torr) | 900 m3h-1 |

| 530 ft3min-1 | |

| Ultimate vacuum | 5 x 10-3 mbar |

| 4 x 10-3 Torr | |

| Maximum back pressure – standard (optional*) | 1150 mbarA |

| 2,0 psig | |

| Power consumption at 10 mbar (7.5 Torr) | 17,1 kW |

| 23,2 Hp | |

| Standard motor | 30 kW |

| (380 – 400V, 3 ph, 50 Hz) | |

| Standard motor | 40 hp |

| (200 – 460V, 3 ph, 60 Hz) | |

| Cooling water flow rate (adjustable) | 10 – 20 lmin-1 |

| 2,64 – 5,28 galmin-1 | |

| Cooling water supply temperature range | 5 – 35 oC / 41 – 95 oF |

| Cooling water supply pressure | 2 – 10 barg |

| 29 – 145 psig | |

| Seal purge flow (maximum), regulated to 0.3 – 0.5 barg, (5 – 7 psig) | 24 l min-1 |

| 0,85 ft3min-1 | |

| Seal purge supply pressure | 2 – 10 barg |

| (minimum – maximum) | |

| 29 – 145 psig | |

| Noise (max. with exhaust silencer) | 82 dB(A) |

| Weight (with frame and standard motor) | 1710 kg |

| 3765 lbs | |

| Process connection, inlet | 6” ANSI/DN150 |

| Process connection, outlet | 3” ANSI/DN80 |

| Pumping mechanism |

Applications

• Processes.

• Distillation.

• Drying.

• Evaporation/Crystallisation.

• Solvent/Vapour Recovery